Facility and Equipment

Infrastructure

The Centre houses a GMP compliant Classified Cleanrooms for production and packaging, a GLP compliant prototype product development and Quality Control Laboratory on the third floor Katz building at the University of Alberta.

Cleanroom Gowning area

Cleanroom formulation facility (class 10,000)

Cleanroom filling area (class 1000)

Prototype laboratory

Equipment

DDIC researchers offers their expertise in formulation of special and conventional dosage forms ranging from tablets and capsules to microemulsions, ointments, creams and nanoparticles. The equipment is suited for small scale development of dosage forms and scale-up capabilities of the equipment is an important factor for projects allowing successful transition to commercial production.

Double Cone Blender Single Cone Blender

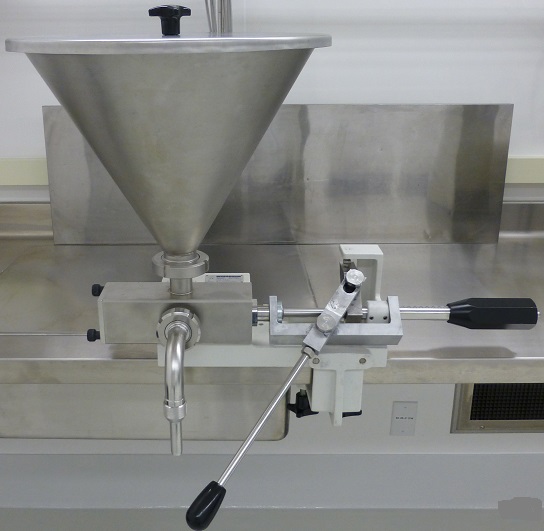

Tube filler Ointment mill

Product Development

Main product development equipment and clinical trial material equipment housed at DDIC include -

Mixers and Blenders

Analytical Balances

Granulators

Rotary tablet press with instrumentation

Freeze Dryer

Spray Dryer

Emulsification equipment

Suppository maker

Grinders for controlled size reduction

Comill

Capsule filling equipment (000, 00, 0, 1)

Blister packaging

Customized labelling

Ointment maker and dispenser

Containment chamber

Fluid Bed granulator

Water Purification system

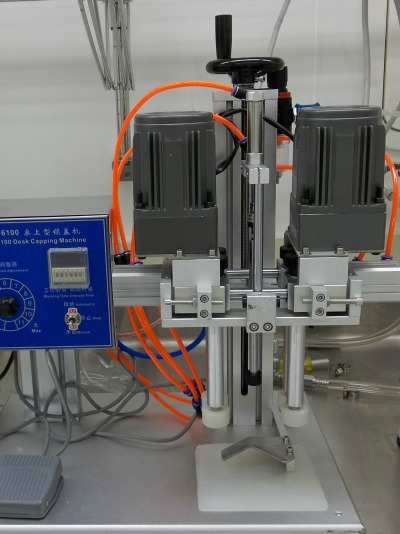

Screw Capping Machine Tablet Counting Machine

Fluid bed dryer Tablet Press and de-duster

Quality and Performance Characterisation Equipment

The quality control and performance testing labs are equipped with modern analytical equipment including -

Thermal activity monitor

Dissolution testing apparatuses (1, 2)

Franz Cell (for performance testing of special dosage forms)

Flow through Cell (for performance testing of special dosage forms)

Soxhlet extraction apparatus

Disintegration testing apparatus

Tablet hardness tester

Friability tester

Weight Checker

Thermal conductivity tester

HPLC Systems for chemical analysis

Stability chambers

Dissolution testing apparatuses HPLC System

Weight Checker Capsule Filler

Quality Statement

The center performs all activities in accordance with regulatory guidelines and organizational accountability requirements. We are committed to scientific excellence, superior quality standards and effective project management in all collaborative and third party research.

The Quality Management System was designed to minimize the risks and establish checks and balances to avoid deviations. The facilities and equipment comply with the regulatory requirements as per the GMP and GLP guidelines. The documentation practices are at par with the industry standards and ensure proper control, data accuracy, traceability and accountability. A LIMS system supports the logistics and material management of the Centre.